Take the next step in developing your products or expanding your product line with a contract manufacturing partner. If you’re struggling to identify the perfect flavor or need a cosmetic formulator to create that all-natural beauty product you’ve been dreaming of, then it’s time to review the formulation and flavoring processes.

See how a leading contract manufacturer can help you prepare your new line of products for the market.

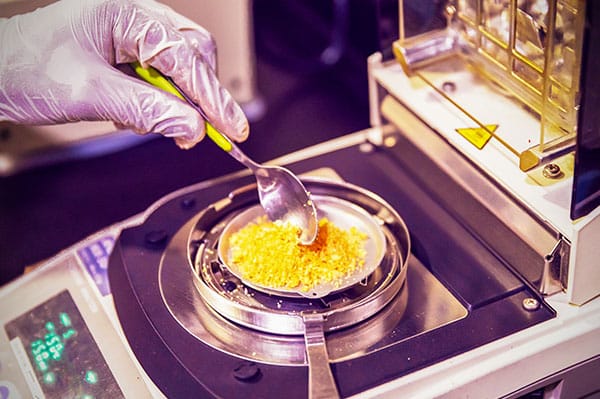

The Formulation Process

It all starts with a dream for your product and brand. This dream needs to translate into a product formula, correct packaging, and proper manufacturing process before it can be enjoyed by your customers. A liquid or powder manufacturing team can help you take the necessary steps to finish this process.

There are two basic ways you can go through the formulation process. First, you can work with a team to take your existing product and transform it into a repeatable formula for large-scale production.

You don’t need to have a finalized product to partner with a contract manufacturer. Bring your dreams of a new product to the team at Maple Mountain Co-Packers to kick off the research phase of your latest cosmetic or food item.

From Blend to Full Production

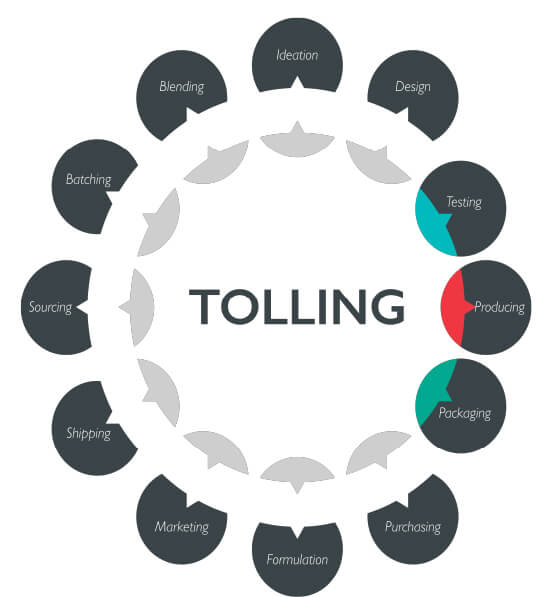

If you already have a blend that you’re ready to mass produce, then the MMCP formulation contract manufacturing team can help you get there. You can start this process at almost any stage of the formulation product. Partner with the MMCP team at any of these stages to prepare for full production:

- Raw ingredients

- Detailed formula

- Finished goods sample

A cosmetic formulator can take raw ingredients or a prototype and create a detailed formula for repeatable production. You don’t need to have a carefully crafted plan to move forward. Bring in what you have and see how an experienced team can move forward with it.

From Dream to Formula

You’ve just had the perfect idea for a new beauty product or energy bar, but you aren’t sure how to make it a reality. A standard food product or powder manufacturing team may not have the necessary resources to help you achieve your finished product. In this situation, you need a product development team.

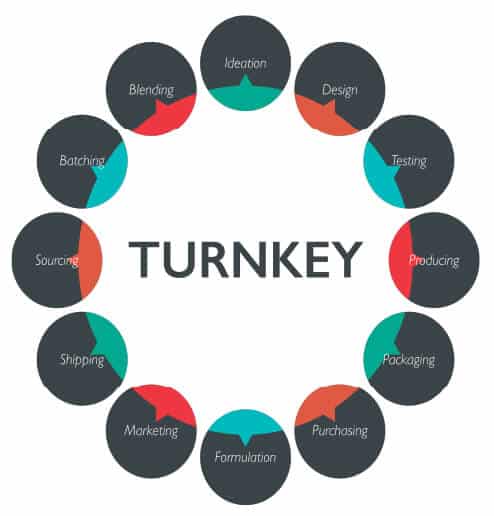

With MMCP, you can enjoy turnkey solutions to move from dream to product manufacturing. Schedule a consultation to see how your contract manufacturing partner can help you develop a new product with these steps:

- Research ingredients and packaging for your proposed item

- Create and test a formula

- Identify claims that match the formula

- Pair the product with high-quality packaging

- Start the manufacturing process

Whether you’re looking for the latest flavor combination or dreaming of a product that uses a trending ingredient, a product development team can help you realize your goals. The research and experimentation steps of this process can be particularly time-consuming, so turn these tasks over to a trusted partner.

Flavoring Options

In addition to creating a formula for liquid or powder manufacturing, a reliable manufacturing team can help you create new flavors for existing products. See how these services can help you expand your line, craft personalized products, and grow your business.

Flavoring for Your Target Market

Your competitor just launched a new line of products. Your customers have been calling for custom flavors. Your sales are stalling. There are many situations that may call for a refreshed product line or the launch of a totally new product.

The first step in launching a new product is identifying your target market. Is your target audience willing to invest in all-natural ingredients, or do they prefer a broad range of tantalizing flavors, scents, and colors? You can perform this research on your own or work with the team at Maple Mountain Co-Packers to find the answers you need.

Once you identify the desires of your target market, it’s time to experiment with flavors and formulations. Only after careful product testing and market analysis can you be confident that you’ve developed a competitive product.

Expanding Your Product Line

If you already have a successful line of products, then it may be time to expand your offerings with custom flavors. Your contract manufacturing team can help you start with your existing product formula and experiment with new flavor alternatives.

Turn to MMCP if you already have flavor requests from your customers. The product development team can identify the best ingredients to add to your proven formula to create this new option.

If you don’t have any recommendations from your customers, then your contract manufacturing partner can research options and provide samples of original flavor combinations. Test out these samples with your target market before finalizing the formula of your new product.

Benefits of Working With a Contract Manufacturing Company

Whether you’ve been working with a formulation contract manufacturing team or creating your own formulas, consider working with a leading team for your next product. Professional formulation gives you the resources you need to identify claims you wish to make and create products that meet those claims.

A contract manufacturing company can also help you scale your business. Transition from small-batch production to large-scale manufacturing to enjoy reduced costs and improved timelines.

Save time and reduce the stress of creating competitive products. Turnkey manufacturing solutions handle everything from formulation to packaging and delivery to ease the stress and workload of owning and operating a business.

Learn More About Maple Mountain Co-Packers’ Services

Produce custom flavors and stunning product additions with expert food and cosmetic formulator services from Maple Mountain Co-Packers. Explore MMCP’s packaging services to see how you can enjoy full-service support to build, produce and deliver winning products.