Turnkey Manufacturing vs. Toll Manufacturing

Turnkey Manufacturing vs. Toll Manufacturing

If you’re a business owner, you may have heard or read a lot about toll manufacturing versus turnkey (or “contract”) manufacturing. You may have even heard the terms used interchangeably, which only adds to your confusion.

What’s the difference between turnkey manufacturing and toll manufacturing? Does toll manufacturing offer any unique benefit? Which type of manufacturing process is best for handling laminating and coating services?

In this post, we’ll address these and other questions, so you can choose what’s best for your business needs.

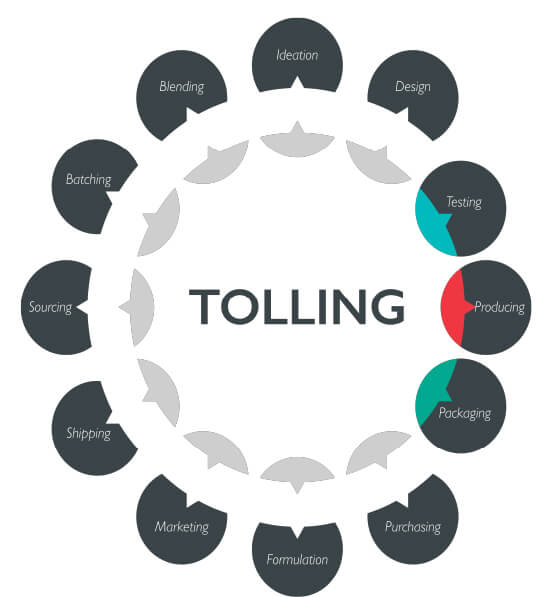

What is Toll Manufacturing?

Toll manufacturing is the simpler of the two manufacturing relationships. In toll manufacturing, the production service renders the tools, equipment, and human resources needed to manufacture the product. You, the business owner, provide any raw materials necessary for the finished product.

Advantages of Toll Manufacturing

Toll manufacturing affords your company a greater degree of ownership over the finished product. Not only can a business owner control the quality of raw materials being used, but they also retain ownership over the intellectual property, including any patents, trademarks, or other “branding” related to the company or finished product.

Disadvantages of Toll Manufacturing

The only downside to toll manufacturing is the level of coordination it requires. The various pieces of toll manufacturing have to come together (i.e., raw materials, manufacturing company, and so on) to produce a finished whole. This part of the process can occasionally slow production down, and sometimes the price of raw materials can fluctuate, adding to manufacturing costs.

If you need additional coating or laminating services, toll manufacturing becomes even slower and costly. Plus, many business owners may be unfamiliar with packaging standards or the types of coatings they may need for toll manufacturing.

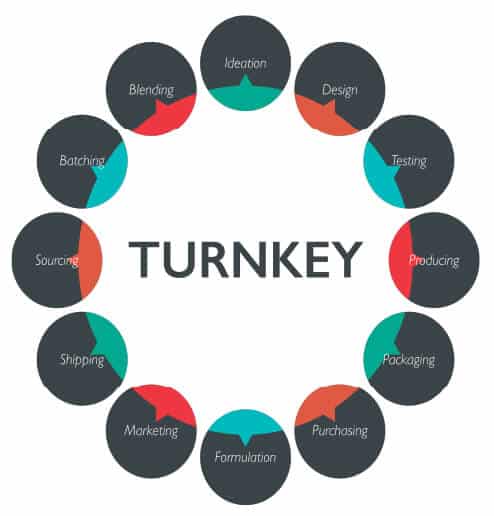

What Is Turnkey Manufacturing

Turnkey manufacturing or contract manufacturing operates similarly to toll manufacturing. The crucial difference is that the turnkey manufacturing company provides the raw materials necessary for the finished product.

Advantages of Contract Manufacturing

The advantage of a contract manufacturing relationship is that the manufacturer typically bears related turnkey manufacturing risks such as the cost, the level of stocks, and selecting which raw materials to use. Contract manufacturing is very much a “hands-off” approach for the business owner. This strategy results in a much faster manufacturing process than toll manufacturing. You simply hand over the job to a contractor and wait for the finished product.

Contract manufacturing may be particularly beneficial for businesses whose product packaging requires a specialized coating. A larger company may be able to provide the raw materials for coating and laminating services—something you might not be able to do through a toll manufacturing contract.

Disadvantages of Contract Manufacturing

With contract manufacturing, the turnkey manufacturing company retains a great deal of sovereignty over the kind of raw materials being used, which can be particularly important for those who need to consider their product’s packaging and coating quality. In some cases, contractual arrangements mitigate the risks of contract manufacturing, such as pricing provisions or manufacturing warranties.

The Key Difference Between Toll and Turnkey Services

The difference between toll manufacturing and contract (or turnkey) manufacturing lies mainly in who provides the raw materials. If you enter into a toll manufacturing relationship, you will have to provide the raw materials for your product. If you enter into a contract manufacturing relationship, the manufacturing company provides the raw materials needed for your packaging and coating needs.

Because a coating is essential for many finished and semi-finished products, business owners should carefully weigh their options before entering into a contract.

What Businesses Benefit from Toll Manufacturing?

Toll manufacturing tends to favor businesses seeking to produce smaller quantities of products on an as-needed basis. If you own a small business, your manufacturing needs might be more sporadic than regular, and you may wish to retain the rights to your intellectual property. And if you have the time to devote to the task, you also have the advantage of selecting just the suitable materials you need for your product.

On the other hand, a toll manufacturing contract may present you with some specialized decisions. What sort of packaging materials do you need to get? What type of coating is best for your finished product? A turnkey manufacturing service grants you greater flexibility, but you may have more pressing concerns than packaging or coating needs.

You may find that these kinds of decisions are best handled by a professional company that’s more accustomed to high-volume contracts and may have connections to provide the best, most affordable packaging and coating services currently available.

What Businesses Benefit from Contract Manufacturing?

Contract manufacturing is a much simpler process. If you’re a business owner, you may value a company that handles the packaging of your products and assists with both your packaging and coating needs, depending on your requirements.

Contract manufacturing relationships can also offer some basic design support services, so you don’t have to worry about the overall design of your product’s packaging.

Additionally, if your business requires specialized packaging and coating services, outsourcing these needs to a reputable company can be a wise business decision. Typically, obtaining suitable materials for product coating involves time and attention to detail. A contract manufacturing partner may have the resources necessary to get just the right materials for the best product packaging and coating. Because these resources can be bought in bulk, they may be available more cheaply through a contract manufacturer than through a toll manufacturing contractor.

Contract Manufacturing and Packaging

Contract manufacturing and packaging services can be invaluable to ensure that your product receives the best quality packaging, including the best coating needed for product distribution. For most business owners, choosing a coating may seem to be too small a detail to have to contend with regularly. By partnering with a larger company, you can ensure your packaging needs are met, with a coating whose quality matches your product.

Maple Mountain Co-Packers

Maple Mountain Co-Packers offers contract packaging services designed to provide lower costs and faster deliveries. We understand that time is of the essence; that’s why we ensure that we form partnerships with our clients to meet their deadlines, all while providing packaging and coating services for a variety of manufacturing needs.

If you’re looking for a packaging partner that can help your business flourish and grow, contact us today.